In packaging, when you hear the word “sustainability” it usually refers to the type of material. Compostable and organic materials are often glorified, while other materials are excessively demonized despite having a considerably lower environmental impact if properly recycled.

As an example, take Pet plastic bottles: they can provide raw material for new containers, which can be recycled once again in a virtuous circle triggered by technological innovation and careful study of materials.

Monomaterial Packaging

This virtuous circle gave birth to a new kind of packaging, which is a perfect fit for completely green production and distribution cycles and well-suited to support circular economies.

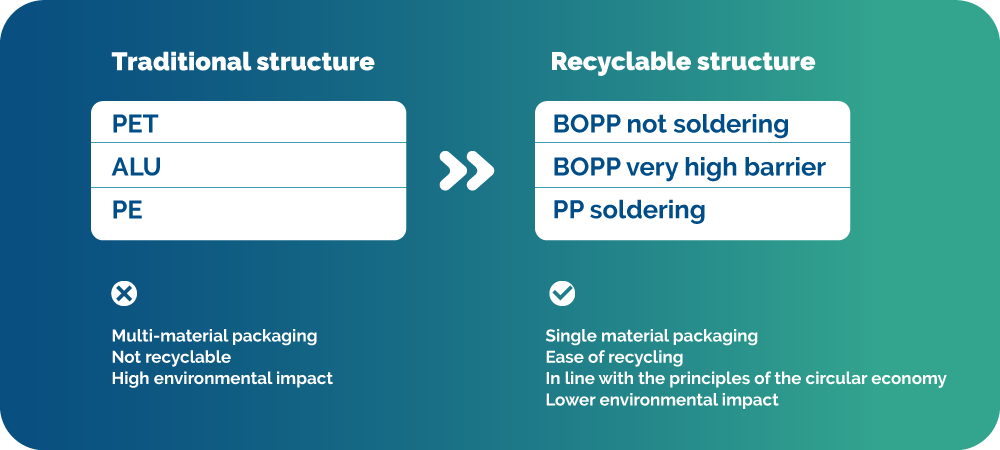

We are talking about monomaterial packaging, a type of casing produced from a single polymeric material and a promising step towards European Union’s goal to ensure all plastic packaging will be recyclable or reusable within 2030.

The present and the future of non-paper flexible packaging (as preserving paper compostability would require lamination with non-established, expensive and low-performing vegetal films like PLA or Mater-Bi) is recyclable monomaterials, which fit nicely within circular economy strategies, can be an energy source and provide some interesting advantages:

- they are easily recyclable for both end users and industries choosing to invest in green solutions;

- they are eco-friendly and safe, as several laboratory tests identified tough and high-performing materials;

- they are carefully controlled and can minimize the risk of contamination.

Among the many monomaterial packagings designed to meet market and circular economy needs, one of the most challenging was the coffee packaging. For its conservation, coffee requires zero permeability films, a feature that until recently only aluminium could provide.

We at Maca developed and industrialized a solution with aluminium-like performances, fully recyclable and potentially viable for the entire coffee product line: from pods and monodose capsules to one-kilogram coffee beans bags or one-quarter kilogram airtight bags.

This solution features a layer of top-level high-barrier BOPP film, designed to replace aluminium or metallized materials for products sensitive to oxygen, light and moisture (like coffee, for instance). The film has also been tested to provide the best possible protection from mineral oil migration.

In addition to the many monomaterial flexible packaging advantages, this solution also allows to:

- apply top coating (matte paint, paper touch);

- give the print a metallized effect by employing metallized high-barrier BOPP without affecting the recyclability of the final product.

Our monomaterial films are fully recyclable as we use the same type of plastic for each layer and the print is environmentally sustainable as well. For our films we use flexographic printing with water-based paints, which make packaging even more eco-friendly.

The struggle to achieve Positive Packaging is not only a matter of materials, but also of Human Design. Packaging companies must certainly face the challenge to produce environmentally sustainable solutions, but they also need to make the recycling process for packs as simple as possible for industries and people. Only together as a community of people and institutions in pursuit of a common goal we will succeed in making a positive change.

Go forward. But also go together.